MIL-DTL-18045G

3.3.3 Body strap and leg straps. Body strap and leg straps shall be

made of 1-inch nylon webbing (see 3.2.3) in accordance with the applicable

drawings in section 2. The body strap assembly shall have a breaking strength

of not less than 360 pounds when tested as specified in 4.5.5.

3.3.4 Inherently buoyant foam pads. There shall be four front pads

(one upper and one lower pad on each side of the front) and one back pad.

Type I, III life preservers shall also have one collar pad. The pads for the

front and back may be made from a maximum of three plies of foam permanently

bonded together equaling 2-1/2 inches in thickness.

The buoyant foam pads shall be

3.3.4.1 Distribution of buoyant medium.

cut in accordance with Drawing 803-1419482.

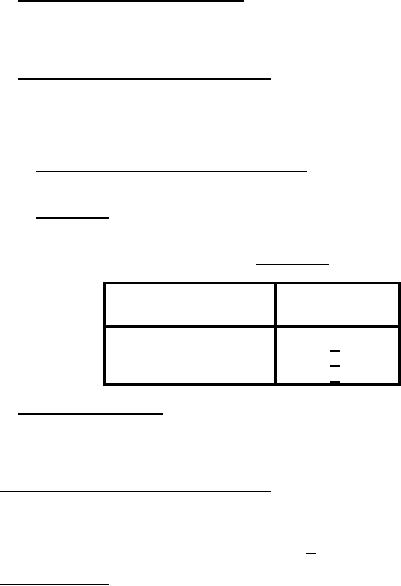

3.3.4.2 Buoyancy. The pads shall have the buoyancies specified in

table I when tested as specified in 4.5.6.

TABLE I.

Buoyancy.

Buoyancy

Pad

(pounds)

7.0 + 0.5

Back pad

4.0 + 0.5

Upper front pad

7.5 + 0.5

Lower front pad

3.3.5 Inspection label. A label conforming to DDD-L-20, type VI, class

1, 2-1/2 by 3-1/2 inches, shall be sewed on the bottom of the jacket on the

inside of the lining. The printing on the tag shall be in waterproof black

ink and shall be in accordance with Drawing 803-1419479.

3.4 Stitches, seams, and stitching. Stitches shall be type 301 in

accor- dance with FED-STD-751 and shall be 8 to 10 stitches per inch. Seam

types and stitching types shall conform to the applicable drawings of FED-STD-

751, unless otherwise specified (see 6.2). Reflective tape stitching shall be

around the outer perimeter of the tape, 3/16 + 1/16 inch in from edge of tape.

3.5 Construction. The manufacture and assembly of type I and type II

life preservers shall be in accordance with Drawings 803-1419479, 803-1419480,

803-1419481, and 803-1419482, as applicable. Actual construction shall be in

accordance with the operations shown in table II, for type I preservers and

table III for type II preservers. The contractor is not required to follow

the exact sequence of operations, provided that the finished items are

identical to those produced by following the sequence as listed in tables II

and III.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business