MIL-L-850E

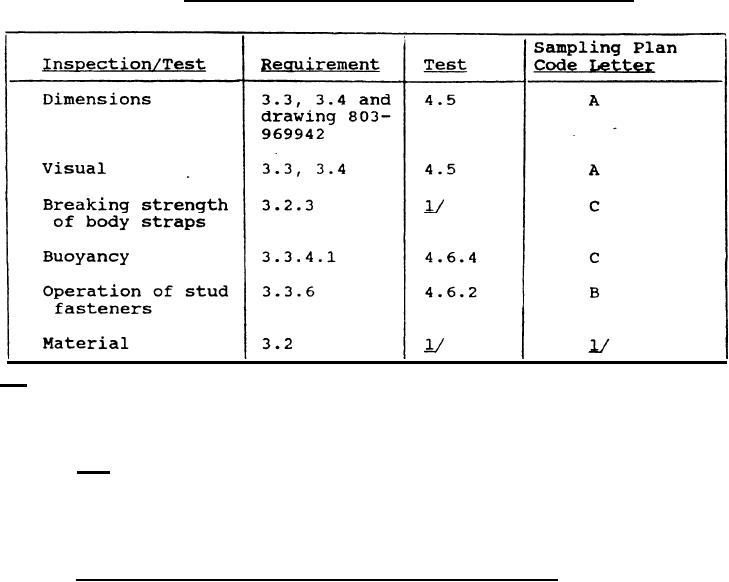

TABLE II. QUALITY CONFORMANCE INSPECTION AND TESTS.

1 / Notes:

Material certification or material test results shall

be maintained to establish identity and traceability

of materials used for each lot of life preservers.

4.4.1 Lot.

For purposes of quality conformance inspection and

test sampling, a lot is defined as all life preservers produced

in one facility, using the same materials and production

processes, and being offered for delivery at one time.

Lot size

shall not exceed 3,200 life preservers.

4.4.2 Samp ling for quality conformance inspection. As a

minimum, the contractor shall randomly select a sample quantity

from each lot of completed life preservers in accordance with

Tables 11 and III and inspect them in accordance with 4.5 and

4.6. Samples size depends on the sampling plan code letter

shown in Table II.

If one or more defects are found in any

sample, the entire lot shall be rejected.

The contractor has

the option of screening 100 percent of the lot for the defective

characteristic(s) or providing a new lot which shall be inspected

in accordance with the sampling plan contained herein. The

contractor shall maintain for a period of three years after

contract completion, records of inspections, tests, and any

resulting rejections.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business