MIL-D-87030B(SH)

Three cotton laundering cycles shall be performed on 8 by 6 inch specimens

using 1/4 inch double laminated foam.

The distance between the clamps shall be 2 inches at the start of the test.

Slitting the specimen between the nylon knit and foam to help separate the

fabric from the foam sufficiently to fit the clamps is permissible. The

adhesion shall be tested in the fabric's length (wales) direction and on

one side only of the 1/4 inch foam laminated on both sides.

Specimens 4 by 4 inches shall be placed together fabric side to fabric side.

Cemented seams shall be centered equidistant from the clamps, Breaks

shall be made with the seam at right angles to load direction. The clamps

shall be 1 inch apart at the start of the test and the face of each jaw

shall be not less than 1 by 2 inches. The cemented seam test specimen

shall be rectangular, 2 inches wide by not less than 4 inches long.

The test shall be performed on specially prepared cemented seams,

reinforced seams and fused seams, similar to those made on the end item.

When preparing specimens of the reinforced and fused seams for testing, a

minimum of 1 inch tab shall be left free to facilitate testing for

adhesion strength.

The specimen shall be suspended vertically in the air-oven at 158 ± 2

degrees Fahrenheit (°F) for 7 days. At the conclusion of the aging

interval the specimens shall be cooled at room temperature on a flat

surface and allowed to rest 4 hours before determination of adhesion.

4.6.1.1 Compression set under constant deflection. The circular die used

prepare standard test specimens shall have an inside diameter measurement of

1.129 ± 0.001 inches. Test specimens shall have a 1 square inch surface area

with the top and bottom surfaces parallel to each other. Thickness of test

specimens shall be 1/2 inch. If a 1/2 inch thick specimen is not readily

available, then two 1/4 inch thick specimens may be plied to obtain the required

1/2 inch thickness. The apparatus and procedure shall be the same as that

described in method B of ASTM D 395. The test specimens shall be compressed to

50 percent of their measured original thicknesses. The test shall be run at room

temperature for 22 hours. The load shall be released at the end of the test

period and the thickness measured after 24 hours at room temperature. Thickness

shall be measured as specified in ASTM D 1056. Chromium-plated metal plates are

not required for the apparatus. Any stiff plates that are clean and smooth may

be used.

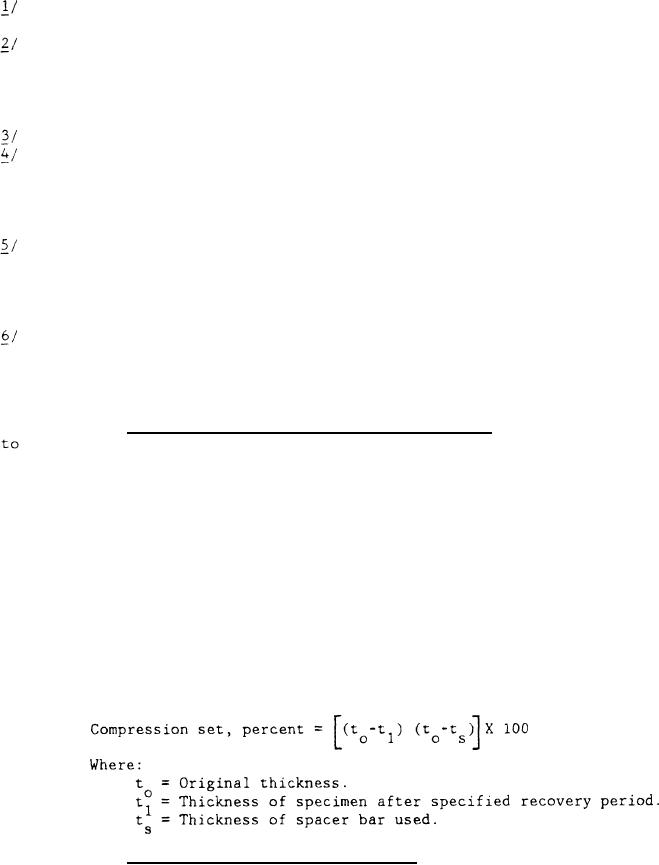

Calculate the percentage compression set as follows:

4.6.1.2 Shrinkage after accelerated aging. Three

specimens each with a

minimum dimension of 8 by 8 inches shall be measured to

the nearest 1/32 inch

in both length and width by means of a steel rule. The

specimens shall be

days. At the conclusion

suspended vertically in the air oven at 158 ± 2°F for 7

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business