MIL-D-87030B(SH)

Packaging defects.

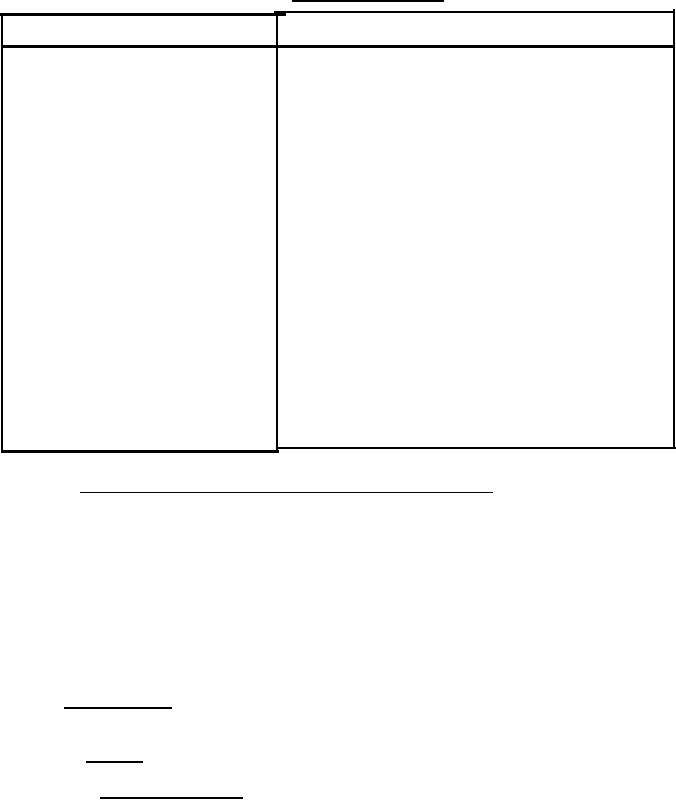

TABLE IX.

Defects

Examine

Omitted; incorrect; illegible; of

Marking (interior)

improper size, location, sequence

and exterior)

or method of application.

Any component missing, damaged, or

Materials

not as specified.

Inadequate application of compo-

Workmanship

nents , such as polyethylene

bags with heat-sealed seams that

are crooked, noncontinuous, open

or not parallel.

Tie down tapes not properly

secured.

Closure of shipping container not

as specified. Bulged or distort-

ed containers.

Number of suits per shipping

Content

container is more or less than

required.

4.9.1 Inspection of interior and exterior containers. When interior and

exterior containers are required to be in accordance with PPP-B-636 or

PPP-B-601., examination for-defects in the assembly and closure (for fiberboard

containers) shall be in accordance with the appendix of the applicable container

specification.

PACKAGING

5.

(The packaging requirements specified herein apply only for direct Govern-

ment acquisition. For the extent of applicability of the packaging requirements

of referenced documents listed in section 2, see 6.7.)

Preservation shall be level A or commercial as speci-

5.1 Preservation.

fied (see 6.2.1).

5.1.1 Level A.

5.1.1.1 Polyethylene bag. Each divers dress suit, with sleeves in

natural position over body front, shall be placed full length within a flat

style clear polyethylene film bag having a minimum thickness of 0.004 inch

plus or minus 20 percent tolerance. The bag shall be formed with heat sealed

seams that are straight, continuous, and parallel to each other and the formed

edges of the bag. The final closure of the bag shall be heat sealed with the

seal made as close as possible to the open end. The bag shall measure 76

inches in length by 32 inches in width (plus 1 inch minus O tolerance)

(see figure 4).

23

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business