MIL-PRF-87108B

chamber. Following the vacuum leak test, when measured using a scale accurate to at least 0.002

lbs, there shall be no loss in weight.

4.4

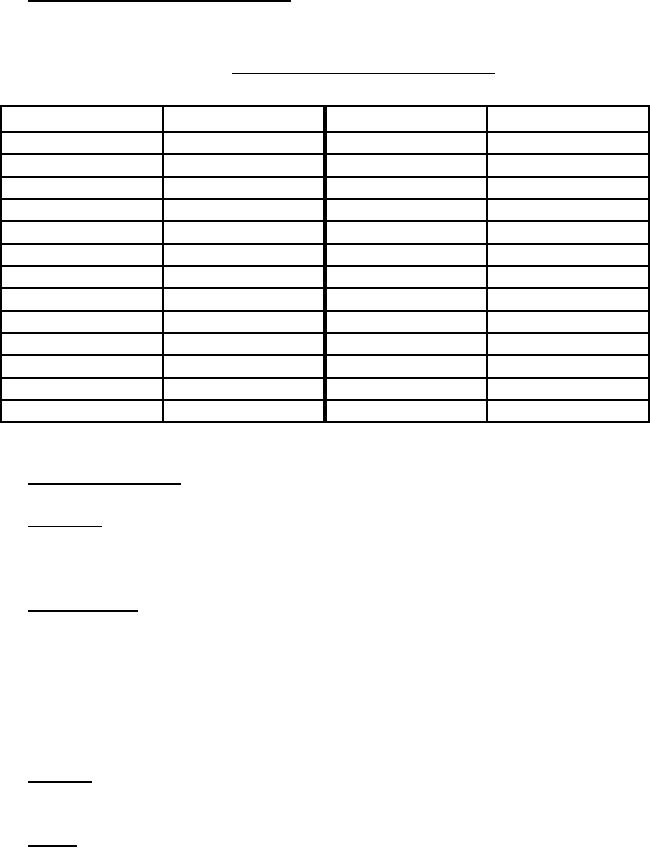

Requirements cross-reference matrix. Table I provide a cross-reference matrix of the

section 3 requirements tested or verified in the paragraphs below.

TABLE I. Requirements cross-reference matrix.

REQUIREMENT

VERIFICATION

REQUIREMENT

VERIFICATION

3.3

4.6.1

3.7.3

4.6.8

3.4

4.6.1

3.7.4

4.6.9

3.4.1

4.6.1

3.7.5

4.6.16

3.4.2

4.6.1, 4.6.9

3.7.6

4.6.10

3.4.2.1

4.6.1

3.7.7

4.6.11

3.4.2.2

4.6.1

3.7.8

4.6.12

3.5.1

4.6.1

3.7.9

4.6.13

3.5.2

4.6.3

3.7.10

4.6.14

3.5.3

4.6.1

3.8

4.6.15

3.5.4

4.6.1

3.9

4.6.1

3.6

4.6.1

3.10

4.6.1

3.7.1

4.6.4, 4.6.5, 4.6.6

3.11

4.7

3.7.2

4.6.7

4.5

Inspection conditions.

4.5.1 Test items. Unless otherwise indicated in the test procedures, all performance,

environmental, and test requirements are based on an inflation device complete with replaceable

components.

4.5.2 Test conditions. Unless otherwise specified in the test procedures, all required tests shall

be conducted under the ambient conditions, i.e., atmospheric pressure of 28 to 32 inches of

mercury, temperature of 59 to 95 °F, and relative humidity of not more than 80%. If conditions

change during a test, the test shall be suspended and appropriate corrections applied before

resuming the test. Unless otherwise indicated in the test procedures, test sample temperature

conditioning shall be at least one hour longer than that required for the sample to reach thermal

equilibrium.

4.5.3 Nitrogen. Where gaseous nitrogen is specified for an inspection method, grade B of

BB-N-411, type 1, class 1 shall be used.

4.5.4 Drying. Unless otherwise specified herein, the inflation assembly shall be thoroughly dried

upon completion of any inspection that requires it to be immersed in a liquid.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business