MIL-PRF-27639D

4.7

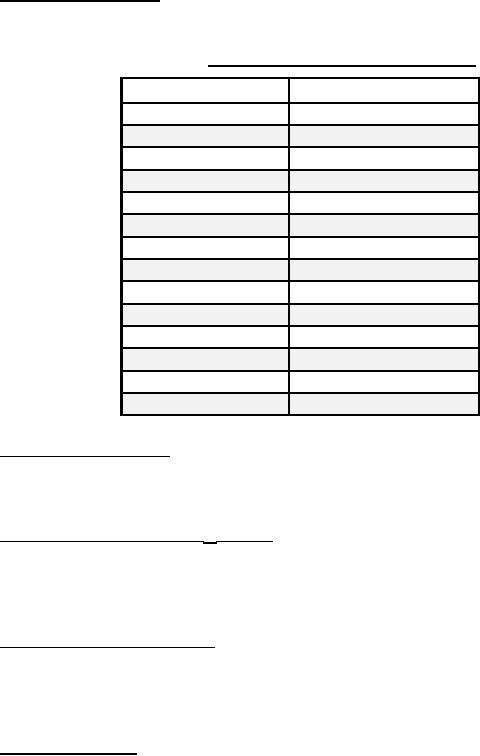

Methods of inspection Table 1 provides a cross-reference matrix of the requirements

.

tested or verified in the paragraphs below.

TABLE 1: Requirements cross-reference matrix.

REQUIREMENT

VERIFICATION

3.9.1

4.7.2

3.9.2

4.7.3

3.9.3

4.7.4

3.9.4

4.7.5

3.9.5

4.7.6

3.9.6

4.7.7

3.9.7

4.7.8

3.9.8

4.7.9

3.9.9

4.7.1

3.9.10

4.7.1

3.9.11

4.7.1

3.9.12

4.7.1

3.9.13

4.7.1

3.9.14

4.7.10

4.7.1 Examination of product Each inflator valve shall be visually examined to determine

.

compliance with the requirements of this specification with respect to workmanship, materials,

markings, dimensions, weight, and interchangeability as cited in section 3.

4.7.2 Operation test without CO2 cylinder. The inflator valve shall be held in an inverted

position with a 2-pound load attached to the actuator with the actuator held in the normal

position. The load shall be released and the actuator shall operate the piercing mechanism. The

actuator safety restraint shall not be used to secure the actuator during this test.

4.7.3 Piercing mechanism operation The piercing mechanism shall be operated through its full

.

range of motion. The mechanism shall not be capable of piercing the CO

2 cylinder while in the

stored position when it is subjected to a vibration frequency specified in the procuring document

(see 6.2).

4.7.4 Actuator operation. The actuating lever of each inflator valve shall be operated through

an arc of not more than 90 degrees. The piercing mechanism shall pierce the installed 2CO

cylinder and then retract to its original position with a travel of the actuator through an arc of not

more than 90 degrees in line with the longitudinal axis of the inflator valve.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business